Grasping In-Mold Decorations: Strategies, Trends, and Ideal Practices for Ideal Outcomes

In the world of production, the art of in-mold decorations stands as a critical aspect of item design and manufacturing. As sectors continually look for innovative means to improve aesthetic allure and performance, mastering the ins and outs of in-mold decors has arised as a vital capability. From selecting the ideal products to incorporating cutting-edge design fads, the journey in the direction of achieving ideal lead to this domain name is diverse. By diving right into the strategies, fads, and finest techniques that underpin successful in-mold decoration procedures, services can open a world of opportunities that not only boost the aesthetic appeal of their items however also enhance production performance and strengthen customer involvement.

Material Option

Material selection is a critical facet of grasping in-mold designs, as it directly impacts the high quality and sturdiness of the last product. When choosing products for in-mold decorations, it is necessary to consider elements such as compatibility with the molding procedure, the wanted aesthetic outcome, and the environmental problems the product will certainly face.

In addition, materials with high warmth resistance are chosen for in-mold designs, specifically for products that will be subjected to elevated temperatures during their lifecycle. By carefully selecting the suitable product for in-mold designs, makers can enhance the overall high quality and sturdiness of their products, fulfilling the assumptions of both clients and end-users - In-Mold Decorations.

Layout Technology

An essential variable in progressing the field of in-mold designs is the continual exploration and application of layout development strategies. Layout development plays an essential role in improving the aesthetic appeal, capability, and overall top quality of items produced making use of in-mold decor procedures. By integrating innovative design elements, suppliers can differentiate their products out there, attract customers, and remain in advance of competitors.

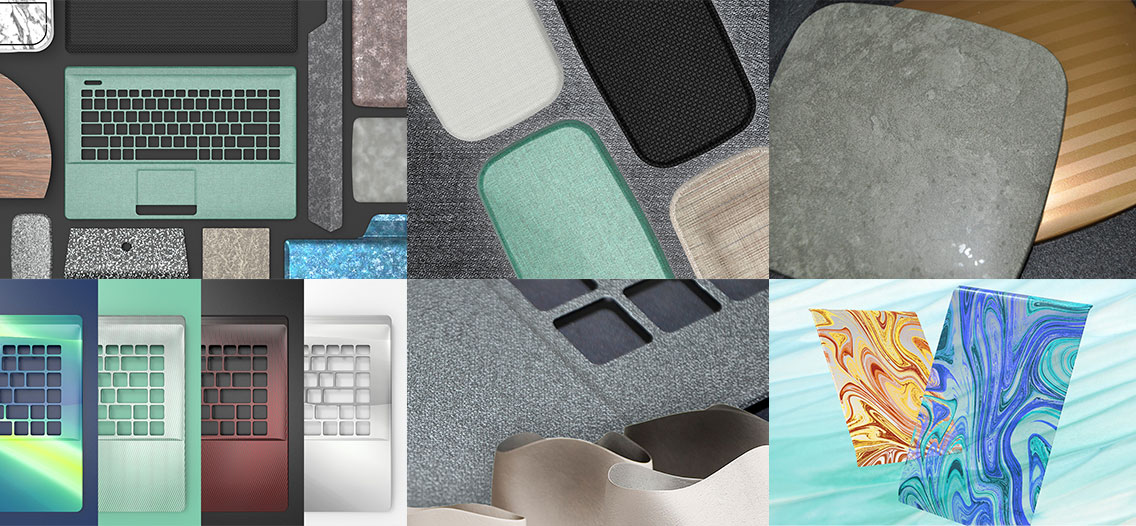

One of the key aspects of design advancement in in-mold designs is the integration of detailed patterns, textures, and graphics that were previously testing to attain with standard decor approaches. Advanced technologies such as 3D printing and digital style devices enable designers to create complex and in-depth layouts that can be effortlessly moved onto molded parts. In addition, making use of vibrant colors, metal finishes, and unique impacts like gloss or matte structures can even more elevate the aesthetic appeal of in-mold enhanced items.

Moreover, design technology expands beyond appearances to encompass practical enhancements such as ergonomic shapes, incorporated functions, and adjustable components that accommodate details individual demands. By welcoming layout technology, manufacturers can open new possibilities for creative thinking, product, and customization distinction in the affordable landscape of in-mold designs.

Manufacturing Effectiveness

Effective production processes are important for equating the cutting-edge styles created in the area of in-mold designs right into top notch completed items that satisfy market demands and consumer expectations. In the world of in-mold designs, manufacturing efficiency encompasses numerous essential facets that contribute to the overall success of the manufacturing procedure. One crucial aspect is why not find out more the optimization of mold design and tooling to make certain smooth and precise decoration transfer onto the last product. By fine-tuning mold setups and buying high-quality tooling products, makers can improve performance and uniformity in production.

Automation not only speeds up the production procedure however also enhances accuracy and repeatability, leading to an extra uniform and premium end item. On the whole, an all natural technique to Learn More production effectiveness is critical in maximizing the capacity of in-mold decor methods and accomplishing ideal outcomes in the competitive market landscape.

Quality Assurance Actions

What are the essential techniques for ensuring stringent quality control measures in the world of in-mold designs? Quality assurance steps are vital in in-mold decoration processes to make certain the manufacturing of flawless and top notch finished items. One vital method is the implementation of extensive assessment protocols at every stage of the production process. This entails performing extensive aesthetic inspections, dimensional checks, and shade uniformity evaluations to recognize any kind of problems or inconsistencies at an early stage.

Making use of sophisticated innovations such as computerized assessment systems can also boost the quality assurance process by offering exact and trusted information for analysis. These systems can find flaws that might be missed out on by hand-operated inspections, consequently improving general product high quality and consistency.

Normal training and growth programs for workers included in the in-mold design process can also contribute to preserving top notch criteria. By educating team on best techniques, high quality assumptions, and the importance of interest to information, companies can promote a culture of high quality awareness throughout the organization.

Consumer Charm

To enhance the marketability of in-mold design items, providing and understanding to customer preferences play an essential function in establishing their allure and success. Consumer charm in in-mold decorations is influenced by numerous aspects, consisting of layout aesthetic appeals, color options, longevity, and overall functionality. Consumers are significantly seeking customized and special items that reflect their individuality and design. As a result, providing personalization alternatives such as customized layouts, color variants, and textural components can considerably enhance the allure of in-mold decoration items.

Final Thought

In-mold decorations provide a efficient and functional method to enhance product looks. By very carefully selecting products, accepting innovative styles, enhancing manufacturing processes, applying quality assurance this page measures, and prioritizing consumer charm, manufacturers can achieve optimum outcomes. It is vital for business to continuously adjust and boost their strategies to stay competitive in the marketplace. In-Mold Decorations. Understanding in-mold designs calls for a holistic strategy that thinks about all aspects of the production procedure to make certain success.

In the world of production, the art of in-mold decors stands as a critical aspect of product layout and manufacturing. Style technology plays a crucial function in enhancing the visual appeal, functionality, and general top quality of products produced utilizing in-mold decor processes.One of the crucial aspects of layout advancement in in-mold decorations is the assimilation of detailed patterns, appearances, and graphics that were previously testing to accomplish with typical design methods.Effective manufacturing processes are crucial for converting the innovative styles created in the area of in-mold decors into top notch finished products that fulfill market needs and customer expectations. Supplying customization alternatives such as tailored designs, color variations, and textural elements can significantly boost the allure of in-mold decor products.